Predicting Equipment Failure Using Vibration & Wear Data

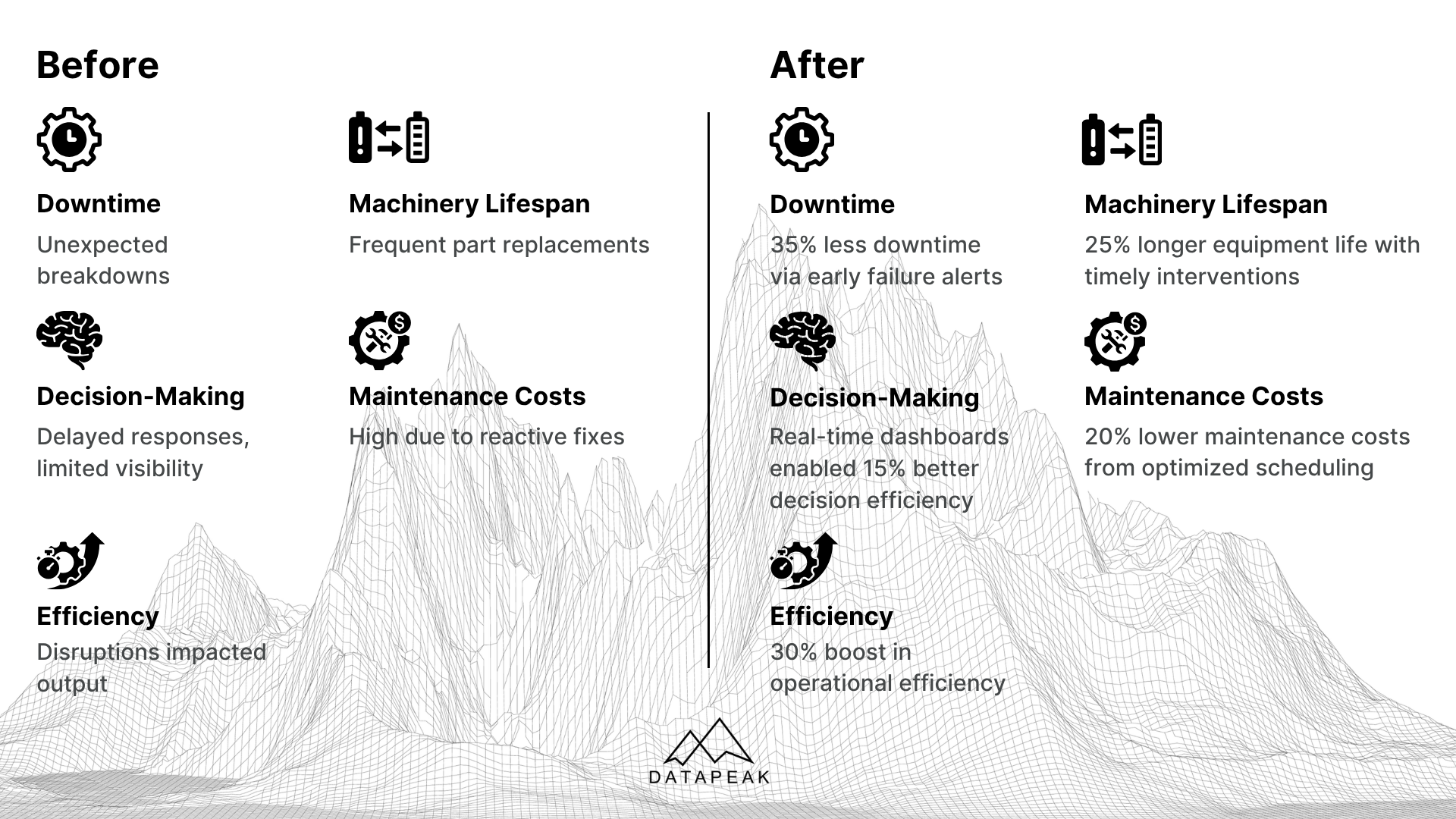

A large international manufacturing company struggled with a familiar (and costly) problem: surprise equipment failures that slowed production, wasted money, and frustrated teams.

Despite having loads of data from sensors, ERP systems, and IoT devices, they couldn't see when their machines were about to fail, especially from wear and vibration.

That changed with DataPeak’s AI-powered maintenance agents.

By using DataPeak to monitor real-time vibration and wear data, they:

Reduced unexpected downtime by 35%

Extended equipment lifespan by 25%

Cut maintenance costs by 20%

The result?

Read the full story of how they did it and see what DataPeak could do for your team.

Real-time monitoring and predictive modelling improved operational efficiency by 30%, ensuring smooth and uninterrupted production processes.

Disclaimer: Results described in this case study are specific to the featured client’s experience. Actual outcomes may vary based on your business context and implementation.