How Manufacturers Can Use No-Code AI to Automate Quality Control

Why Quality Control Needs a Rethink

For manufacturers, quality control (QC) is the difference between strong margins and costly recalls. But traditional QC methods are often manual, slow, and inconsistent. Even when machines assist, they rely on rigid, rules-based systems that struggle to adapt to new variables.

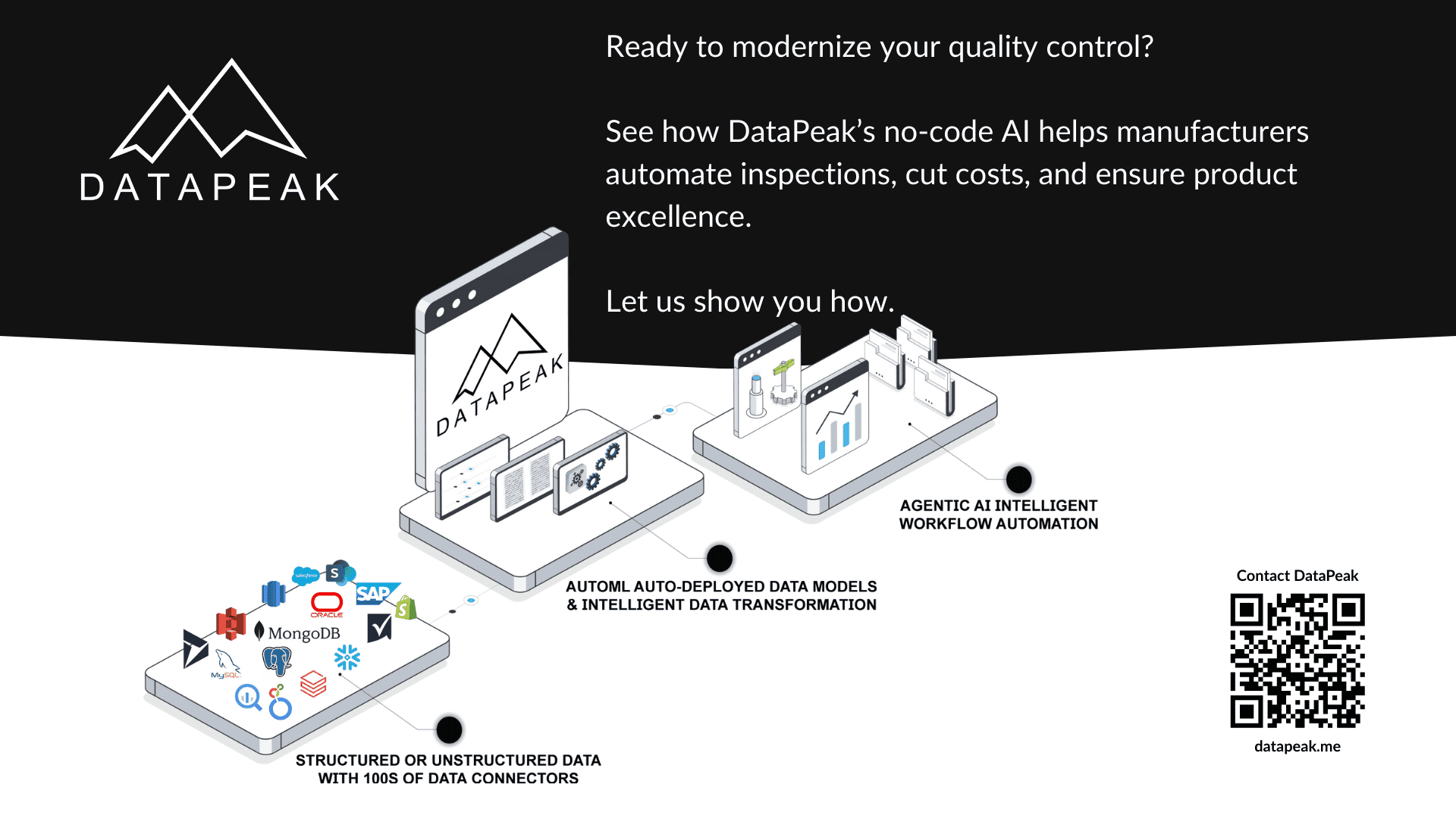

This is where no-code AI enters the picture. With platforms like DataPeak, manufacturers can build automated quality-control processes that are fast, adaptive, and accurate, all without needing coding expertise.

The Problem with Traditional Quality Control

Most manufacturers face the same QC hurdles:

Human error from repetitive inspection tasks.

Slow processes that delay production lines.

High costs of scrap, rework, and warranty claims.

Limited flexibility, hardcoding systems for every scenario is resource-intensive.

As product complexity and customer expectations rise, these weaknesses become more expensive.

What No-Code AI Brings to Quality Control

Unlike rules-based automation, no-code AI adapts in real time. Here’s what makes it different:

Pattern recognition: Detects defects or anomalies from structured and unstructured data (e.g., sensor feeds, images, inspection records).

Adaptability: Learns from new defect types without full reprogramming.

Accessibility: Lets production teams build workflows without coding expertise.

Integration: Connects directly with existing machines, ERP, and MES systems.

The result: faster inspections, fewer errors, and actionable insights for continuous improvement.

Real-World Applications in Manufacturing

1. Visual Inspection

AI agents can review images of products, detecting defects invisible to the human eye.

Catch micro-defects in welds, coatings, or assembly.

Flag products for re-inspection before they leave the line.

2. Sensor Data Analysis

No-code workflows analyze vibration, temperature, and pressure sensor data in real time.

Detect early signs of wear and tear.

Prevent defective products before they’re produced.

3. Automated Reporting

Instead of manual logs, no-code agents generate QC reports instantly.

Include defect rates, pass/fail percentages, and trend analysis.

Feed reports back into ERP or compliance systems automatically.

4. Predictive Quality Control

With historical data, no-code AI forecasts when and where quality issues are most likely.

Identify “high-risk” batches or suppliers.

Reallocate inspection resources proactively.

Example: A Mid-Sized Electronics Manufacturer

Traditionally, a mid-sized electronics manufacturer relied on manual inspections, which slowed throughput and often missed subtle defects. By introducing no-code AI workflows into their process, results could look like this:

Visual inspection accuracy improving by 20%+.

Reporting time dropping from hours to minutes.

Defect-related rework costs reduced by double digits in the first quarter.

The key takeaway? With no-code AI, even non-technical plant managers can design and maintain workflows, no coding required.

Why No-Code Matters in Manufacturing

In manufacturing, speed matters. Teams can’t wait on scarce technical talent to build or maintain QC systems. With no-code AI:

QC teams own their workflows.

Updates happen quickly. If a defect pattern changes, workflows can adapt within hours.

Cost savings scale. Small changes in defect detection can lead to huge bottom-line gains.

Overcoming Concerns

“Will this replace inspectors?” → No. It augments them, letting staff focus on problem-solving instead of repetitive checks.

“Will it work with my existing systems?” → Yes. DataPeak integrates with ERPs, MES, and sensors already in place.

“Is it secure?” → Role-based permissions ensure workflows stay compliant and auditable.

Smarter Quality, Without the Complexity

No-code AI brings flexibility, accuracy, and speed to manufacturing quality control. It’s not about replacing teams, it’s about empowering them with tools that work in real-world conditions.

With DataPeak, manufacturers can reduce defects, save costs, and keep quality high, all without coding expertise.

Keyword Profile: DataPeak no-code AI, no-code quality control, AI in manufacturing, quality control automation, no-code workflow AI