Consolidated Data for Asset Maintenance & Reliability

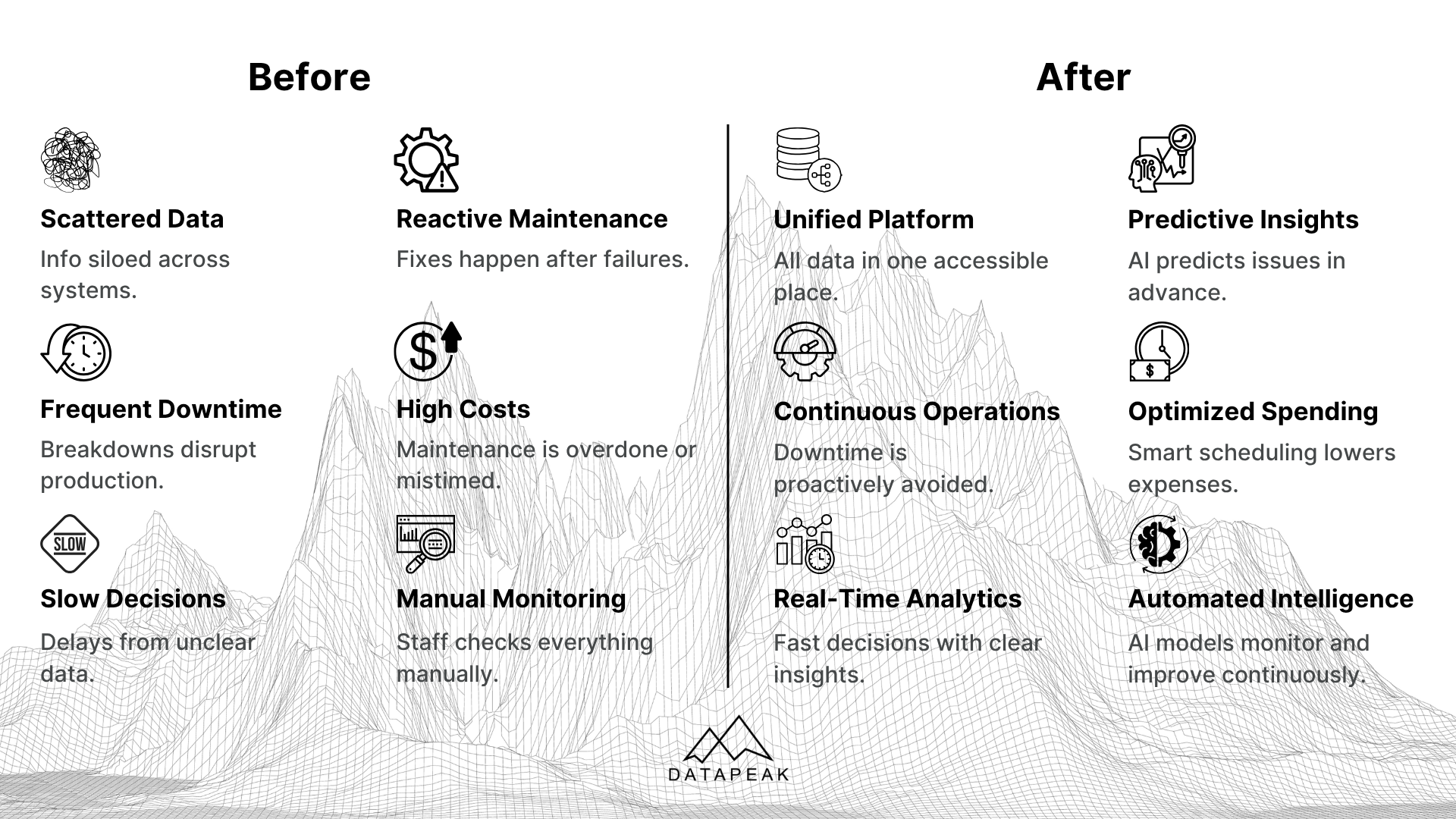

Dr. Oetker, a global food manufacturer, was dealing with frequent equipment failures and costly downtime. Their maintenance systems were fragmented, making it difficult to get ahead of problems before they disrupted production.

By implementing DataPeak, the team:

Integrated siloed maintenance data

Used AI to predict failures and optimize maintenance

Reduced equipment downtime

Saved thousands in maintenance and repair costs

This shift didn’t just improve system reliability. It gave teams the insight and confidence to plan ahead and keep production running smoothly.

Read the full story of how they did it and see what DataPeak could do for your team.

Disclaimer: Results described in this case study are specific to the featured client’s experience. Actual outcomes may vary based on your business context and implementation.